Product Details Introduction

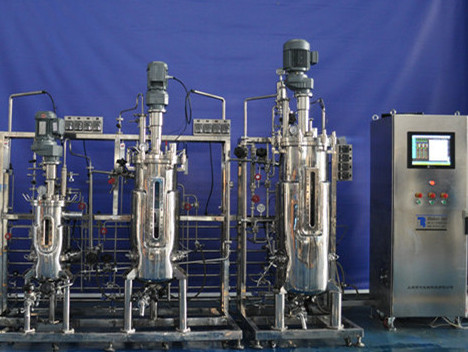

BLBIO-5SJ-50SJ-500SJ 5 L 50 L 500 L three stage fermenter|bioreactor system

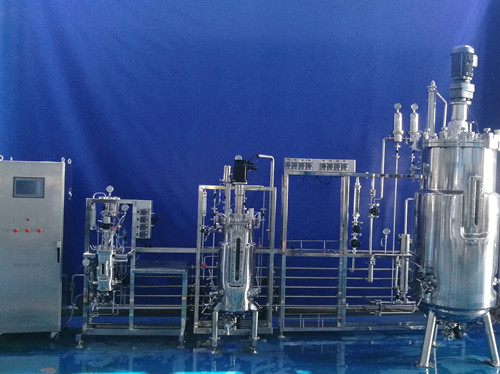

BLBIO-15SJ-100SJ-200SJ 15 L 100L 200 L three stage fermenter|bioreactor

BLBIO-5SJA-50SJA-500SJA 5L 50 L 500 L three stage fermenters|bioreactors

Multi-stage fermentation tank system can be used independently of each tank can also be used simultaneously conjoined; reliable plumbing shift can be sterilized separately; floorstanding / Bench Rack optional, BLBIO-A type, B, C-type , D-type control system Optional: separate control cabinet or centralized control; can be a combination of various fermenters needed for amplification from the lab to test flask fermentation studies of transition, but also can be used for small-scale produce

Size: 5L-30L-100L / 5L-50L-300L / 5L-50L-500L / 10L-100L-1000L / 50L-500L-5000L variety of combinations

Nominal volume: 5L-50L-500L;

Diameter height ratio: 1: 2-3; liquid filling factor: 70%

5 l 50 l 500 l tank: The main material is stainless steel 316L tank, the tank no dead ends; special sampling with fermentation tanks, discharge valve, transplanted pipeline. Using a large tank level perspective endoscopic observation, 12V safety depends on light, with temperature, PH, DO, foaming, liquid interface, vaccination mouth, feeding the mouth, and a number of alternate ports, all welds sturdy neat appearance .

Tank: Design pressure 0.3Mpa jacket: design pressure 0.3Mpa, optimized diversion designed to improve the uniformity of the exchange efficiency and tank temperature

Tank features: John Crane mechanical seals, intake sterile filter, exhaust condenser, including air intake system distributor, flame inoculation mouth (also doghouse and cleaning the mouth), the discharge opening, sampling ports, feeding mouth; five electrode automatic control parameters are: PH electrode, DO electrode, anti-foaming electrode, temperature probe mouth; every four cans were automatically controlled peristaltic pump up the acid / base / bubble enemy / training agents;

Motor: fermentation tank dedicated AC motor, ensure that the motor can operate in harsh environments;

Ventilation: The way deep ventilation, rotameter display, according to the technical requirements of the gas flow regulator, tank air distributor uniform gas; using precision 0.2μm sterilizing filter (Shanghai Yiming), anti-backflow device materials to ensure the safety and greatly extend the life;

Mixing system: mechanical mixing system, SEW AC motor, Fuji inverter

Stir form: straight blade impeller (two) pitched blade impeller (a), mechanical compression type defoaming paddle (a), four-speed material plate;

Fermentation pH control: using intelligent PID control, dedicated Mettler PH electrode;

DO degree of fermentation control: using intelligent PID control, dedicated Mettler DO electrode;

Temperature control: electric heating, water cooling, circulating pump loop temperature control, air and water supply for self-escape function, over-temperature protection, with good heat exchange efficiency; intelligent control module not only ensures rapid temperature control but also realize energy .

Feeding: complete feeding system (acids, alkalis, bubble enemy, training agents), can be time quantitative feeding; four peristaltic pump can select sub-set respectively in the control interface, convenient and flexible in actual use. With a specially designed feeding pins to ensure safe operation of feeding;

BLBIO-C control system: Siemens S7-200 series PLC control system + 10 "LCD touch screen display operation, on-site direct operation (menu-driven), the entire Chinese menu and interface; sampling and analysis show browse tank data, system data read setting controls the stirring speed, temperature, medium tank, Ph value, DO value;

You can set the temperature, speed, Ph value, DO value, the upper and lower limits and have overrun alarm functions;

With ultra-fluid level alarm and automatic function, with super-bubble level alarm and automatically add defoamers function;

All alarms can be recorded incidents inspection;

Speed, temperature, Ph value, DO values, etc., and can be set to automatically shut down;

Tank medium temperature, stirring speed, Ph, DO and other parameters can be set in accordance with process requirements piecewise curve control;

Each parameter has a PID adjustment process shows, such as the set value, real value, PID set value, upper and lower limit value curve display, manual / automatic switch, online setting, etc.;

Historical data and curves of various parameters can be stored for many years, real-time curve during a power outage can re-boot of the restoration;

Friendly interface, you can switch the monitor screen dozen;

Feeding with metering function; time quantitative feeding;

System associated with a variety of control: control speed associated with dissolved oxygen, and dissolved oxygen associated with the control of feeding, feeding the ph value of the associated control and so on;

Real-time display system having a running process, data recording, data analysis

Parameters of the detection and control loops can be manually set and fixed in line on the screen, can be temperature, DO, PH sensor tuning adjustment, calibration of each peristaltic pump flow; operation have password protection, password into the operator and administrator-level password;

Automatically record fermenter boot time, shutdown time, the number of automatic run-time power, power outages, call time

Software system with adaptive ability and self-diagnostic capabilities;

Add optional features items:

b feeding tank weighing scales weighing W d e air flow automatically controlled oxygen tank pressure bypass detection f g h online testing redox potential A (b) alcohol content online testing and control I exhaust O2, CO2 content of online testing A automatic sterilization function C tank automatic cleaning function U lid automatically upgrade function

Model Comments: BLBIO- XABC-D

X- tank total volume:

A- tank materials: -G: Glass / -S: stainless steel tank -V animal cell vaccine -C -M enzyme reactor tank

B- Transmission: -C: magnetic drive mechanical stirring / -J Direct drive mechanical agitation / -Q -S solid flow stir stir -G provide light

C - add optional features -A automatic sterilization - inaction manual manual situ sterilization sterilization -U -Y glass lid automatically upgrade

D - -A controller model for industrial control computer + Control Module - inaction B controller, for our standard controller -C 10-inch LCD touch screen + PLC -D 15-inch LCD touch screen + PLC + imports transmitter Siemens Stainless steel control box is -S

Add optional features items:

b feeding tank weighing scales weighing W d e air flow automatically controlled oxygen tank pressure bypass detection f g h online testing redox potential A (b) alcohol content online testing and control I exhaust O2, CO2 content of online testing A automatic sterilization function C tank automatic cleaning function U lid automatically upgrade function

Model Comments: BLBIO- XABC-D

X- tank total volume:

A- tank materials: -G: Glass / -S: stainless steel tank -V animal cell vaccine -C -M enzyme reactor tank

B- Transmission: -C: magnetic drive mechanical stirring / -J Direct drive mechanical agitation / -Q -S solid flow stir stir -G provide light

C - add optional features -A automatic sterilization - inaction manual manual situ sterilization sterilization -U -Y glass lid automatically upgrade

D - -A controller model for industrial control computer + Control Module - inaction B controller, for our standard controller -C 10-inch LCD touch screen + PLC -D 15-inch LCD touch screen + PLC + imports transmitter Siemens stainless steel control box is -S